I've always been careful around batteries but after experiencing an exploding battery last year on my skidloader right under the seat while I was starting it and experiencing first hand the explosive power and sound I've tried to become even more cautious around them.

After seeing this up close and wondering what if it had happened unattended what might have been the result? So battery disconnect switches look like a good investment to keep things disconnected when not in use and to prevent small losses from draining the battery.

I've never been a big fan of the two 6 volt batteries in series on the 40 and other series Deere's. The batteries are expensive and usually problematic in that they never age or share load and life equally. Which usually means buying 2 new batteries when you really only need one since you try and match them in age and capacity. The other issues are the regular battery cables, they are specialized and expensive and I simply don't like the idea of them under the cab floor where they can rub and the longer lengths further drain cranking power. It also seems like corrosion is always an issue. So the more you clean them the looser they get and pretty soon they won't stay tight on the terminals and start arcing into the clamp or the post eventually ruining one or the other or both. I've replaced the cables a couple times already on the 4040. At first I was tempted to try two 12 volts in parallel and thought about a double battery box like on the 60 series JD's until I saw the price of those. http://talk.newagtalk.com/forums/thread-view.asp?tid=642590 Many here on NAT have commented on the practicality of a single group 31 battery and going to ring type cable terminals and stud type batteries plus shortening up all the cabling. The 4040 had a ground from one battery to the oil filter base on the right side. The cross over cable going from the + on the right side to the - on the left side, and a + going out the back side of the left box back under the floor and behind the cowl panel to the starter lug. This meant 2 of these cables were under the floor in cramped spaces and were always an unknown as to condition and in a hot area as well.

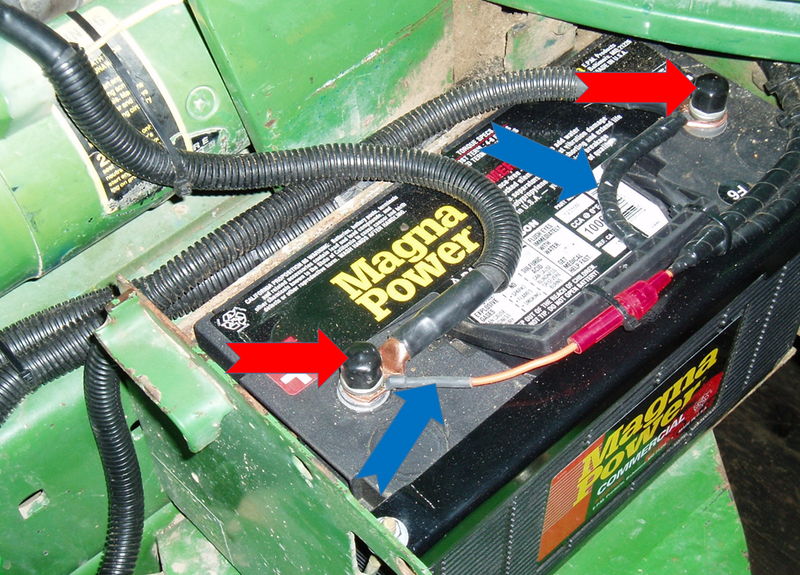

This latest pair of 6 volts had been in since October of 2009 so they had decent life but the long crossover cable had been arcing and had ate into the post and cable clamp. I decided to try one 1000CCA group 31 battery in the left hand box to see how it compared to the 2 sixes in series. I can add another later if I feel the need but so far am pleased with the results. The group 31 battery was about the same overall size but a little taller.

I ended up having about 1/2" of clearance between the top of the stud nuts and the underside of the step top so I had a couple rubber caps I slid over the nuts just to insulate them from any possible arcing. (red arrows) I also had to relocate and slightly modify my leads for my planter monitor power supply. (blue arrows).

A short positive cable goes out the back of the box to the starter solenoid lug. This is about 1/2 as long as the previous cable that went out the end of the box under the floor and back out behind the removable cowl panel.

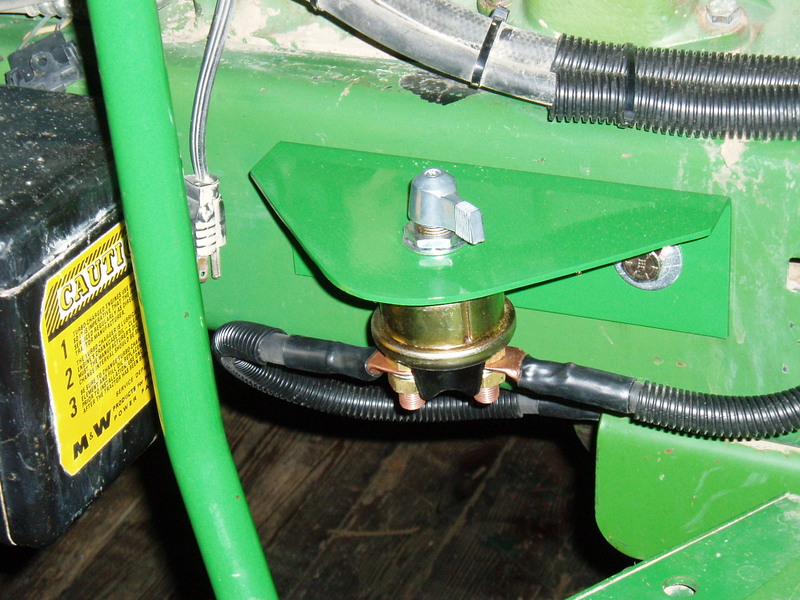

The negative cable comes from the negative stud to one side of the heavy duty disconnect switch I mounted to a piece of angle iron that I cut and bolted to the side frame.

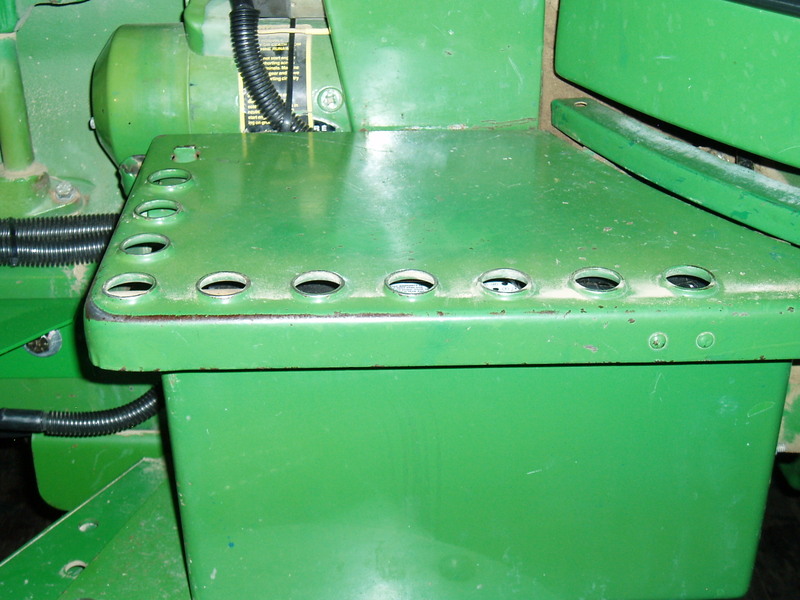

Overhead view of connections.

The other side of the disconnect bolts to a 1/2 bolt that is used to mount the updated steps to the bottom of the frame rail.

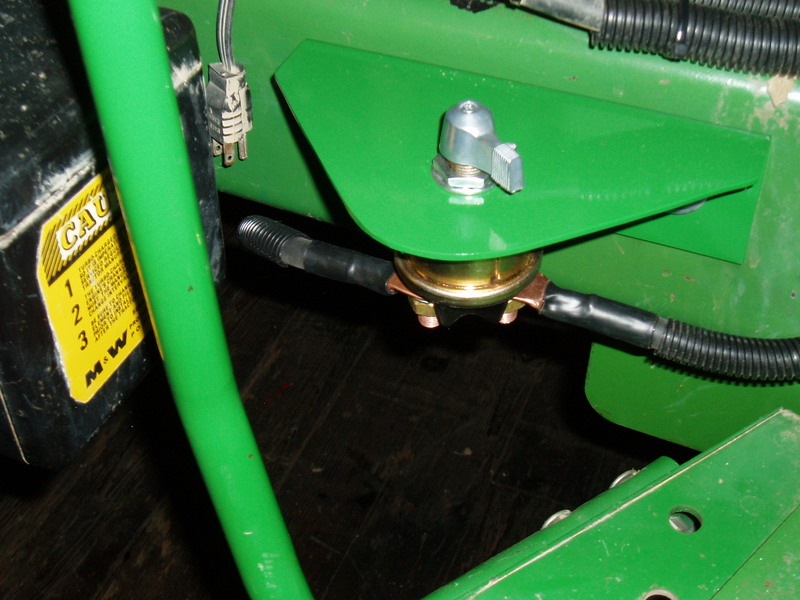

Another view of the cables.

2 AC lines with wire loom to protect the hoses and the 2 new battery cables exiting the battery box.

View with everything put back together.

While this is not quite as neat and tidy as the factory run cabling at least it is all pretty much in one place and protected with wire loom and out in the open and visible where it can be monitored for issues and where you can keep an eye on it. I used 2/0 cable for all the connections with crimped on copper 3/8" or 1/2" diameter rings depending on what was required on the battery studs, disconnect switch and ground bolt. Many thanks to all who commented on their single battery setups, The fine people at Ansonia Auto Parts for answering questions about the disconnect and it's ratings,and durability and the people at the Service Company for the battery, cables, ends, shrink tube, and loom. Cost breakdown was as follows HD disconnect $38.00 1000 CCA group 31 battery $100.00 3 new custom cables with ends, shrink tube and loom $54.00 Paint and steel I already had. Total $192.00 This setup seemed to spin engine over faster than before and had no problem starting tractor. Real test will come later when temperatures drop. Just price checked JD parts. Two 6 volt batteries $162.79 ea = $325.58 Cables depending on which ones by serial number $40.36,$17.90,$37.03, $22.46 Still no disconnect switch included either which gives you a range of $406.30-$420.87 just for batteries and cables. I think I will be going with more group 31 truck batteries custom ring type cables and disconnect switches in the future instead of relying on special high dollar cables that may need to be ordered. Hope this post is helpful in comparing costs and its just my interpretation of how I thought this could be done. Others mileage may vary. Disclaimer below applies. |

JD 40 series 12V battery conversion and disconnect follow up (pics)

JD 40 series 12V battery conversion and disconnect follow up (pics)