Today's project was adding a battery disconnect to the 6620 Titan II combine. I've been adding these disconnects when I have time or when I do battery change overs or replacement. I usually unhooked the main battery ground over winter storage. Even though I use lots of bait blocks for rodent control I was always worried about wiring getting shorted and causing a fire. Also, as a one man show, I harvest, fill truck, then haul to the elevator. That means shutting off a hot combine and leaving. There has been many a time over the years on the way back home I've seen black smoke in that direction. It's a sickening feeling trying to judge distance and direction. Fortunately,it's always been something somewhere else. I try and do a quick walk around before leaving checking for anything that smells funny or hot. This way I can leave everything electrically dead if I want to. That still does not prevent some other condition from causing an issue but it eliminates a dead short. Every since my skidloader battery exploded I've been more cautious and less trusting of batteries in general.

I started out with 2/0 welding cable and crimped a 1/2 ring on one end and a 3/8" on the other end with the hand held hydraulic crimper I got off Amazon.

Then I sealed it with glue lined shrink tubing.

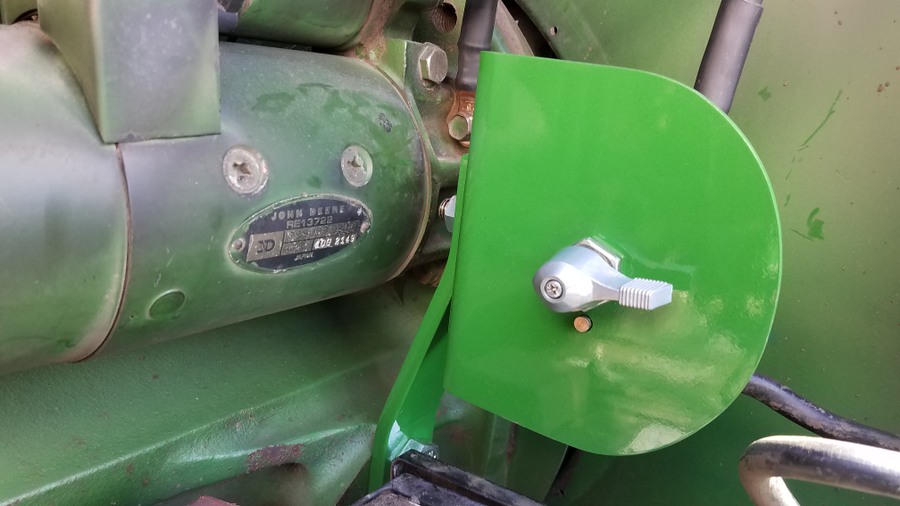

Next I rummaged around in the scrap iron pile and found this piece of steel with a nice offset. I measured and drilled two 3/4" holes in it to mount to the cast pad with threaded holes on the block below the starter. I have a couple sticks of 90° bent 1/8" material for making these switch mounting brackets. I drilled the hole for the switch stem and locator pin for the J&N master disconnect switch #240-22082 that I got locally.

I had originally planned to mount this switch bracket horizontally but it wound up being easier mounting it vertically for easier cable attachment and observation.

The OEM battery cable end was not large enough to drill out to 1/2" to fit on the switch terminal so I took a piece of copper bar and made a lug with a 1/2" hole to fit the switch and 3/8" hole to accept the OEM cable. I bolted the OEM cable to the copper bar with a 3/8" copper bolt and nut so there is no dissimilar metal.

Here is the finished install.

I think these make good additions to any older equipment especially those with lots of wiring or old harnesses that may become brittle with age and heat. At least when you leave the machine you can be sure that it is electrically dead. This may not be the handiest mounting location but I wanted it close to the batteries and the original ground location and the shortest length of cable as possible. Hope this gives others ideas on how to implement something like this. |

6620 Battery Disconnect (pics)

6620 Battery Disconnect (pics)